Facility owners should consider several emerging trends in refrigerant management to ensure compliance with regulations, improve efficiency, and minimize environmental impact. Here are some key trends to plan for:

1. Stricter Regulations and Compliance

- Phaseout of HFCs: Many countries are gradually phasing out high-GWP (Global Warming Potential) refrigerants such as hydrofluorocarbons (HFCs) under agreements like the Kigali Amendment to the Montreal Protocol. This trend means facility owners need to transition to lower-GWP refrigerants (e.g., natural refrigerants like CO₂, ammonia, and hydrocarbon-based systems).

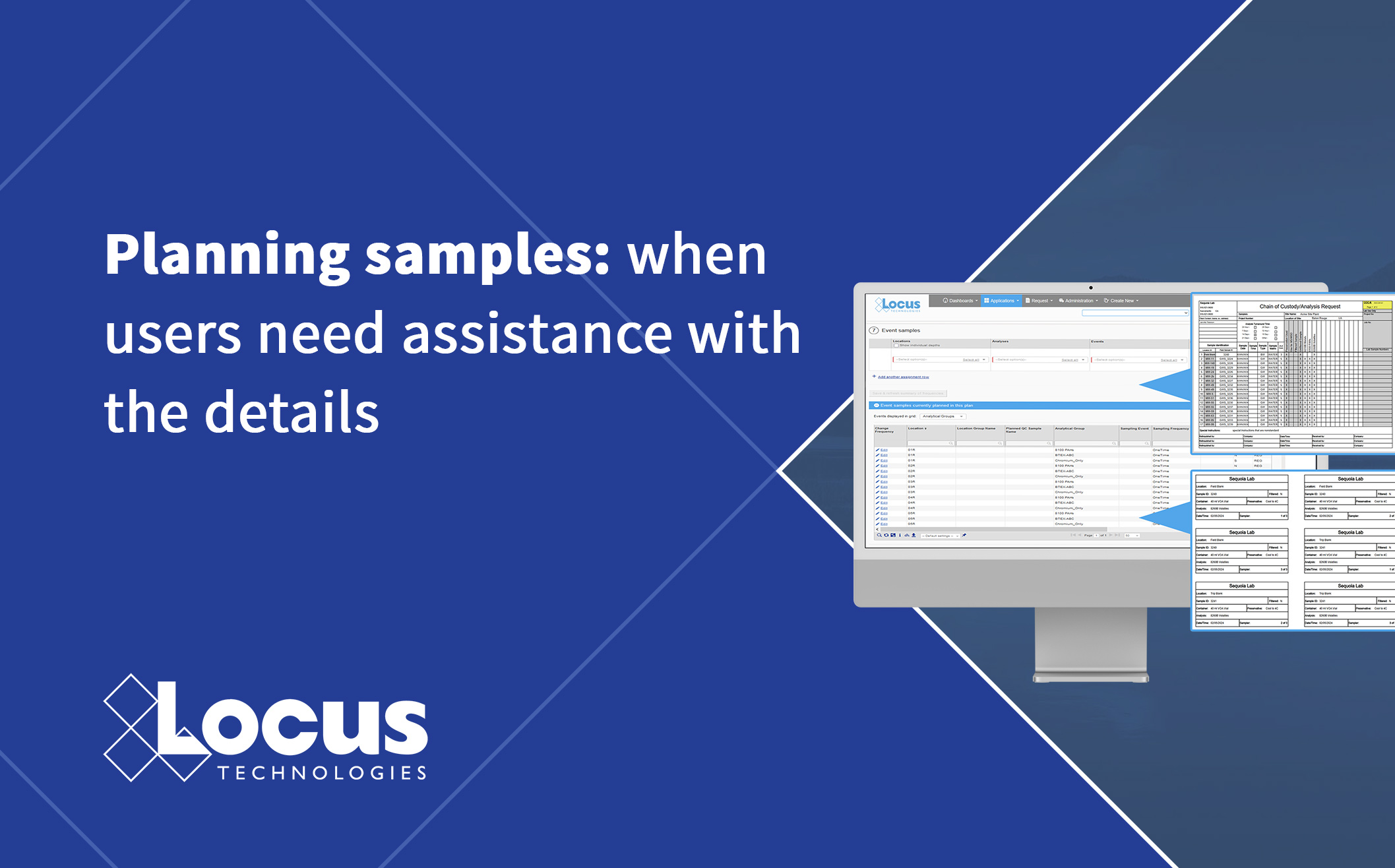

- Increasing Monitoring and Reporting Requirements: Governments are imposing stricter leak detection, reporting, and record-keeping requirements, such as the U.S. Environmental Protection Agency’s (EPA) refrigerant management program. Facility owners must invest in tracking tools and systems to monitor refrigerant use and emissions.

- Carbon Pricing and Penalties: Many regions are introducing carbon taxes or penalties for exceeding certain levels of refrigerant emissions. Owners must be proactive in reducing leaks and minimizing refrigerant usage to avoid additional costs.

2. Adoption of Low-GWP Refrigerants

- Natural Refrigerants: There is a significant push toward using natural refrigerants (e.g., CO₂, ammonia, propane, and hydrocarbons) due to their minimal environmental impact. While these alternatives often require new systems or retrofits, they can offer long-term savings by reducing operational costs and regulatory risks.

- Blends and New Synthetic Refrigerants: Refrigerant blends such as R-32 and other low-GWP synthetic refrigerants are also becoming more popular as alternatives to traditional HFCs. Facility owners should monitor the market for new products that offer both performance and lower environmental impact.

3. Improved Leak Detection and Monitoring Technology

- Real-time Monitoring Systems: As refrigerant leaks contribute significantly to environmental damage and operational inefficiency, real-time leak detection systems are becoming more advanced and affordable. These systems offer facility owners the ability to continuously monitor refrigerant levels, detect leaks, and alert staff for immediate action.

- Wireless Sensors and IoT Integration: Internet of Things (IoT)-enabled sensors for refrigerant systems are becoming common. These sensors can transmit real-time data on refrigerant performance, leaks, and efficiency to central systems, enabling quick decision-making and predictive maintenance.

4. Retrofit and Repurposing Existing Equipment

- Equipment Upgrades: Given the push for lower-GWP refrigerants and regulatory changes, many facility owners are exploring retrofitting older systems to work with more environmentally friendly refrigerants. This approach is often more cost-effective than completely replacing existing equipment.

- Optimizing Existing Systems: In addition to refrigerant replacement, there is a growing emphasis on optimizing refrigeration systems through better design, energy efficiency upgrades, and system adjustments to extend the life of existing assets.

5. Sustainability and Circular Economy

- Recycling and Reclamation Programs: As part of sustainability goals, many facility owners are turning to refrigerant recovery, recycling, and reclamation programs. This helps to reduce the demand for new refrigerants, lowers costs, and minimizes environmental impact.

- Responsible Disposal: Regulations surrounding the disposal of refrigerants are tightening. Proper recovery and disposal methods are essential to ensure that refrigerants do not contribute to ozone depletion or climate change. Owners will need to plan for compliance with these standards.

6. Energy Efficiency and Operational Cost Reduction

- Energy-Efficient Refrigeration Systems: There is a trend toward improving the energy efficiency of refrigeration systems, which reduces operational costs and supports environmental goals. This includes the use of variable-speed compressors, advanced heat exchangers, and automated controls to optimize refrigerant usage.

- Integration with Building Management Systems (BMS): Refrigerant management is increasingly integrated with broader energy management systems to ensure optimal operation of HVACR systems in facilities. BMS integration allows for the tracking of refrigerant levels, energy consumption, and system performance, improving both efficiency and sustainability.

7. Staff Training and Education

- Skilled Labor Shortages: As refrigerant technology evolves, there is a growing need for skilled technicians who are knowledgeable about new refrigerants, leak detection, and system maintenance. Facility owners will need to plan for ongoing training and certification for staff to ensure compliance and efficient operation.

- Training on New Regulations and Technologies: With constant regulatory changes, owners will need to stay updated on new refrigerant management laws and technologies to ensure compliance and avoid penalties.

8. Public and Stakeholder Pressure

- Environmental Responsibility: There is increasing public awareness of the environmental impact of refrigerants. Facility owners will likely face growing pressure from customers, investors, and regulatory bodies to demonstrate their commitment to sustainability. Transparency in refrigerant management and the adoption of low-GWP alternatives will become important factors in corporate reputation.

- Green Certifications: More facilities are seeking green building certifications (e.g., LEED, BREEAM) which often require low-impact refrigerant use. Meeting these standards may require upgrades or changes to refrigerant systems.

9. Innovation in Refrigerant Recovery and Reuse

- Closed-loop Systems: Some industries are developing closed-loop systems where refrigerants are reused in a controlled cycle, minimizing emissions and improving cost efficiency. This is especially relevant for large facilities or industrial applications.

- Advances in Refrigerant Recovery Technologies: New technologies are improving refrigerant recovery, including more efficient distillation and filtration systems that allow refrigerants to be reclaimed and reused multiple times, reducing waste and environmental impact.

By staying ahead of these trends, facility owners can not only ensure regulatory compliance but also reduce operational costs, enhance system efficiency, and contribute to sustainability goals.

Locus is the only self-funded water, air, soil, biological, energy, and waste EHS and ESG reporting software company that is still owned and managed by its founder. The brightest minds in environmental science, embodied carbon, CO2 emissions, refrigerants, and PFAS hang their hats at Locus, and they’ve helped us to become a market leader in compliance and ESG reporting software. Every client-facing employee at Locus has an advanced degree in science or professional EHS experience, and they incubate new ideas every day – such as how machine learning, AI, blockchain, and the Internet of Things will up the ante for EHS, ESG reporting software, and sustainability.