As most people researching EHS software know, the words “configurable”, “multi-tenant”, and “platform” are being discussed everywhere. There are plenty of other great discussions on Platform as a Service (PaaS) and multi-tenancy. Let’s look at some tips for getting the most out of configurable software.

Ask yourself “What sets us apart?”

A key question to ask (as soon as you start thinking about configurable software) is “what sets my company apart?” What special challenges or circumstances make your EHS needs more nuanced or complex?

- Are you in an industry or segment of the industry that may have unique tracking and reporting needs? Maybe you are an organic milk producer or only manufacture snacks from sustainable sources following global fair-trade policies. These more specialized practices may require additional or unique reporting to maintain accreditation.

- Do you handle non-standard materials in highly regulated environments (such as radioactive materials, for example) that impose additional handling, tracking, disposal, and reporting requirements?

- Are you a global enterprise with highly variable reporting needs in multiple jurisdictions? Or are you operating in a location with demanding local regulations?

- Are you operating in an uncertain regulatory environment?

These are just a few of the things that could set EHS customers apart. The more unique or specialized tracking and reporting needs you have, the more you will value the ability to have software easily configured for requirements that are typically not supported in “off-the-shelf” solutions.

Most modern software handles the “basics” very well, but when you have unique or emerging needs—including future needs that you don’t even know about yet—having a configurable option really pays off.

When needs change, configurable software can be updated easily and quickly by the vendor or even your own in-house staff, saving time and avoiding the agony of “waiting for the next release”. And, best of all, those changes can be done by trained configuration staff, without the need for software developers and the cost and time usually associated with software development.

Follow best practices and engage with industry peers

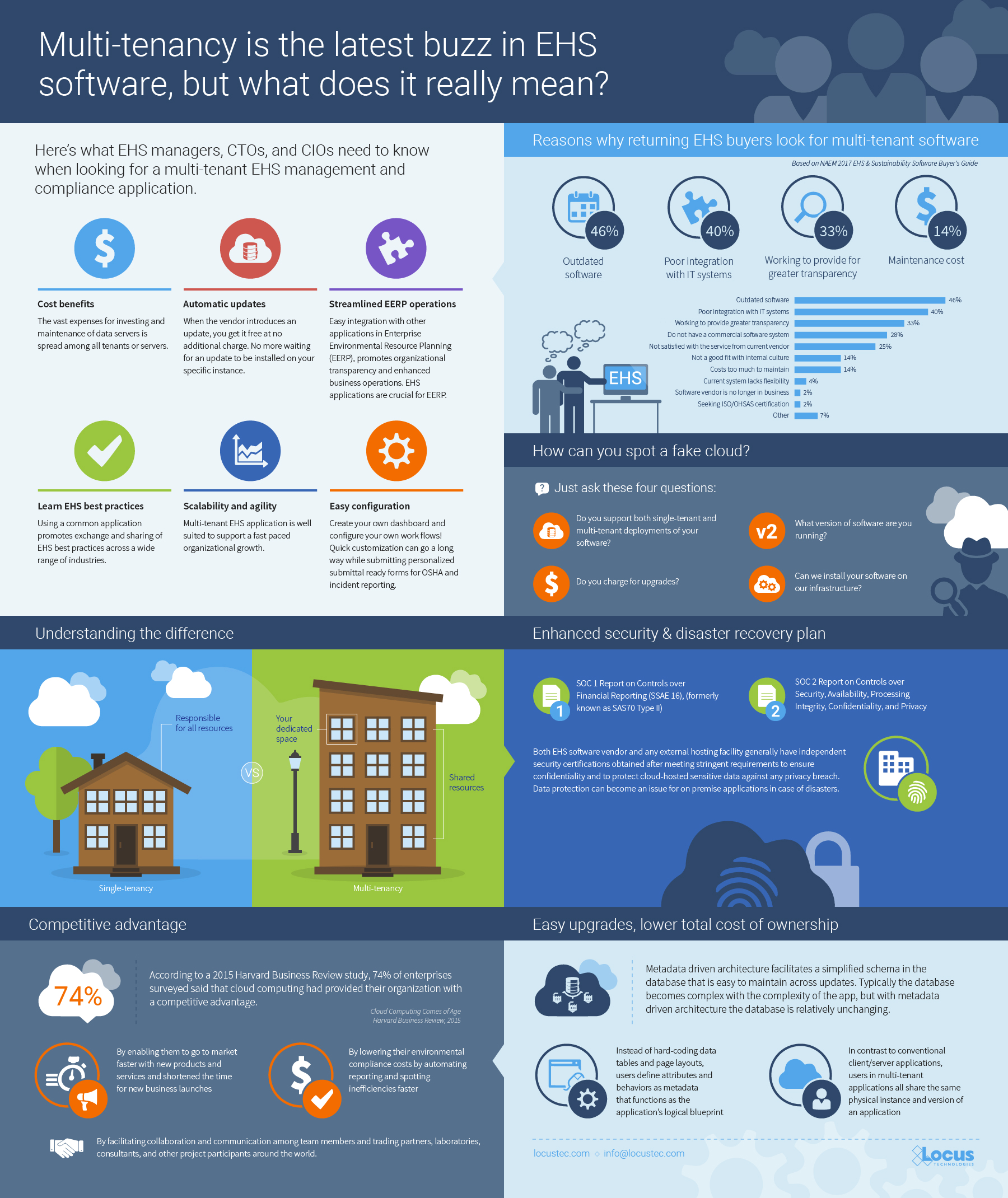

Learning and internalizing industry best practices, a hallmark of the EHS professional association NAEM and its outreach events, can help any software buyer make better choices and evaluate software features, platforms, and key differentiators. Check out the excellent library of resources, including publications, newsletters, and webinars from industry peers. By taking advantage of shared industry knowledge, you can dramatically streamline and expedite your search for the right solutions.

One word of caution: many industry publications can be influenced by sponsors. This is not only true in the EHS domain, but in all industry expert reviews. That’s why actually talking and comparing notes with industry colleagues is an invaluable resource to get beyond the reviews and hear about real-life experiences with the EHS domain itself and the software options that others have actually used.

If you’re looking for advice on how configurable software may be used to address your EHS needs, talking to actual software users will help. Locus, along with many other vendors and hundreds of EHS professionals, routinely attends NAEM’s EHS and Sustainability Software and Data Management Conference in order to meet with potential customers and dive into any questions you may have.

Know the boundaries of configurability

“Configurable” means something different to each software vendor. Some will say “everything is configurable”—for a price. Others will tell you that you can change report names and add a few fields to outputs, and they call this being “configurable”.

Ask the vendor to explain in detail exactly what can easily be configured—and what is “off limits” and requires actual development effort (i.e., additional cost). You might ask:

- Are application workflows easy to change, along with associated notifications and audit tracking?

- Can I change my forms to add five new sections with new lookup values? Will the update be automatically reflected on my mobile forms?

- Can I create an entire new application for tracking volume of green recycling vs. plastics (or anything else you need to track)? Will the new application show up on the mobile app, or is that a separate configuration?

- Can the user interface look different based on the user’s role in the application? For example, could I streamline the interface for my technicians so they only see what is relevant for them?

- Can I change the filter selections on my dashboard reports? How about the charts? Can I add new charts?

By knowing the software’s limitations, you can make better choices on the best fit for your current (and future!) needs. Your software vendor may also identify new configurable features that you hadn’t considered before, but that would greatly improve the usability of the software. Even if you don’t need these options now, knowing you have access to them in the future is critical when selecting software.

Beware the illusion of “the perfect fit”

As we’ve established, “configurable” software can mean anything—from a total blank slate and empty platform, to changing a title of a single data entry field, and everything in between. A “blank slate” may excite more technical people who love to tinker in software programs. For others, the thought of building their software from the ground up might elicit general fear and discomfort.

Most customers want something off-the-shelf that perfectly meets their needs. Honestly, who can disagree? That is the gold standard and what everyone wants. In reality, this solution is hard to find—especially for customers with unique need—and often the software tools that address those unique needs are so focused on a particular niche that they neglect some of the other, more basic EHS needs you might have.

The good news is that configurable software provides almost unlimited options for customers, and it can make a huge difference in how the software fits into your EHS workflow. With some solutions on the market today, you could choose to build one application from a blank slate and make minor tweaks to another pre-built application in the same software.

One of the common pitfalls that EHS professionals frequently encounter in selecting a software solution for a specialized need is the tendency to narrow their options down to limited set tailored to their specific industry. For example, if your organization has requirements for refrigerant handling, you might feel constrained to selecting a solution with specific “out-of-the-box” capabilities for that need. Considering the configurability of the software may allow you to consider new and more robust options, and some simple configurations to an existing chemical inventory application could address your refrigerant reporting needs even more accurately, within a single EHS platform.

Change is inevitable—make sure your software can handle it

Many customers will buy existing applications that meet their general needs, but eventually realize they need another form, a mobile solution, or changes for new regulations. Anyone in the EHS industry knows this is the norm rather than the exception.

According to Forbes, federal departments, agencies, and commissions issued 3,853 rules in 2016, while Congress passed and the president signed 214 bills into law—a ratio of 18 rules for every law. That’s just at the federal level. It’s not hard to imagine the amount of change when you factor in state and local rules and requirements.

Over the anticipated implementation life for your EHS software, you can be reasonably assured that the EHS requirements for your organization are going to be changed in some way. Some of these changes you can anticipate, but not all. Given such routine change, you can safely assume that the more configuration options you have, the more prepared you’ll be for those changes. You’ll be in a better position if you know you can configure your software quickly, rather than waiting for a scheduled vendor update that may be out of your control.

Develop a vision of success—for today and tomorrow

Configurable software can be an effective, sustainable long-term management and reporting solution that integrates smoothly into your existing EHS workflows, but it does require you to do your homework.

You can set yourself up for success with some initial reflection and examination of your organization’s unique needs, a few conversations with industry peers, a healthy skepticism of seemingly perfect “out-of-the-box” solutions, and a willingness to ask tough questions of potential software vendors. Think ahead to the future challenges and regulatory changes that might impact your organization, and make sure your potential software vendor has provided evidence that you’ll be able to handle these changes through configuration. Take the time to truly imagine your perfect application and EHS workflow, and ask the vendor to show how it can be possible through configurability. And finally, don’t be afraid to think outside the box!

About guest blogger— Marian Carr, Locus Technologies

Ms. Carr is responsible for managing overall customer solution deployments and customer relationships with Locus’ government accounts. Her career at Locus includes heading the product development team of the award-winning cloud-based environmental ePortal solution as well as maintaining and growing key customer accounts with Locus’ Fortune 100 enterprise deployments. In addition, Ms. Carr was instrumental in driving the growth and adoption of the Locus EIM platform with key federal and water organizations.

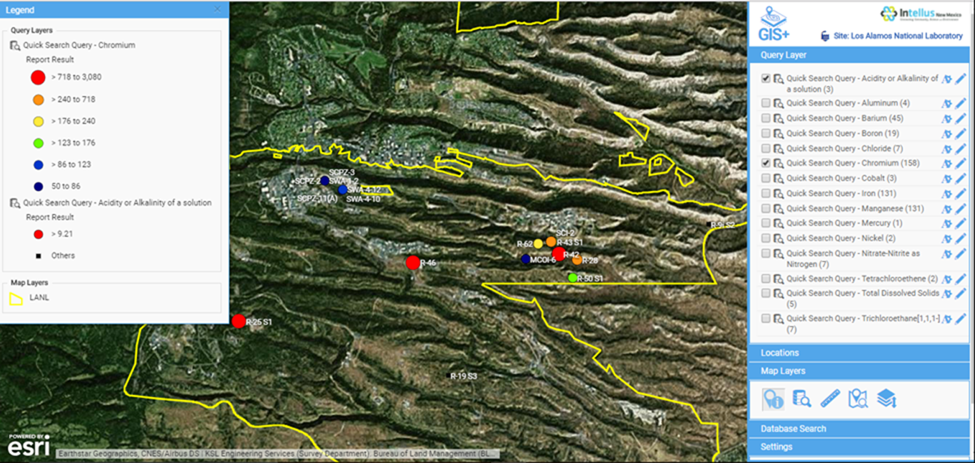

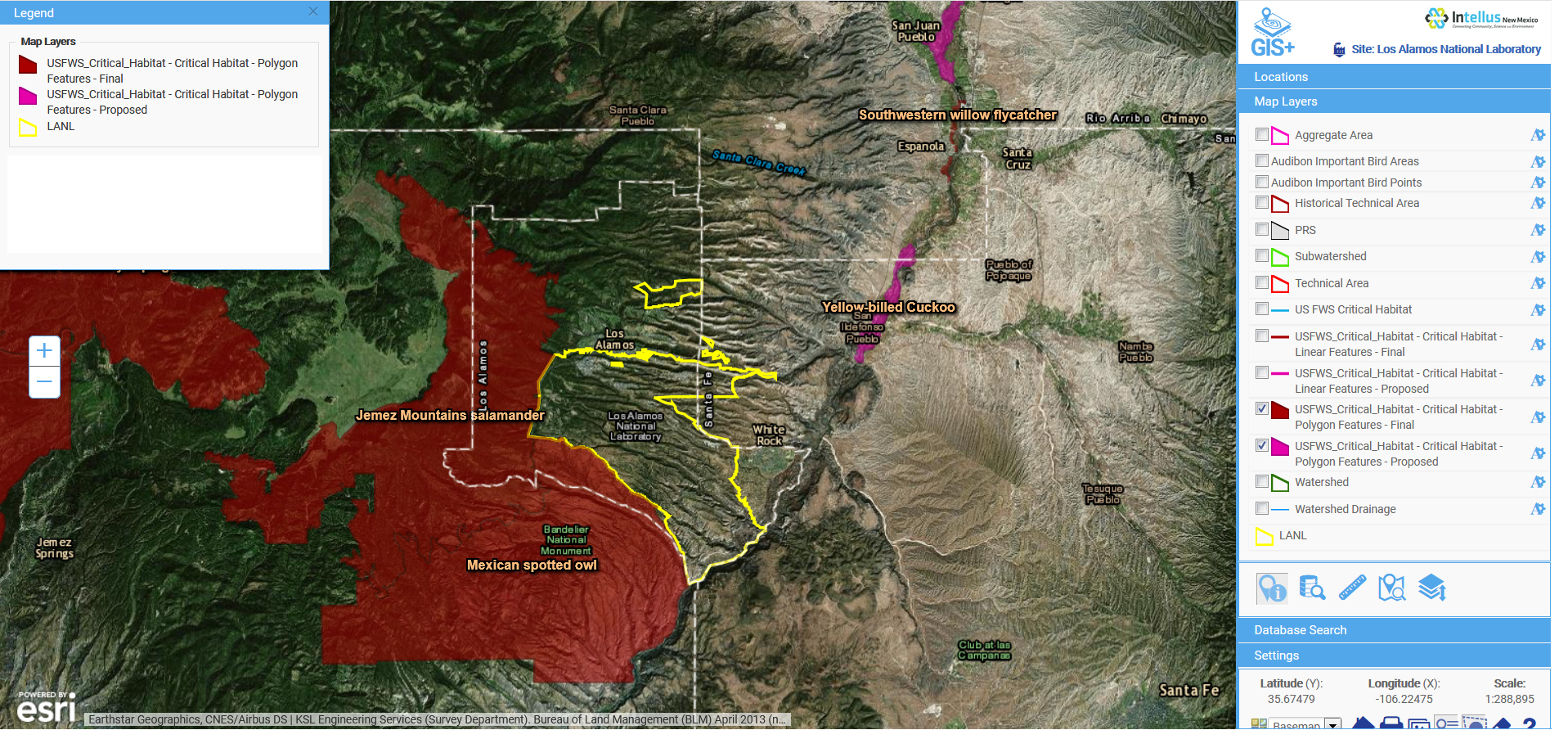

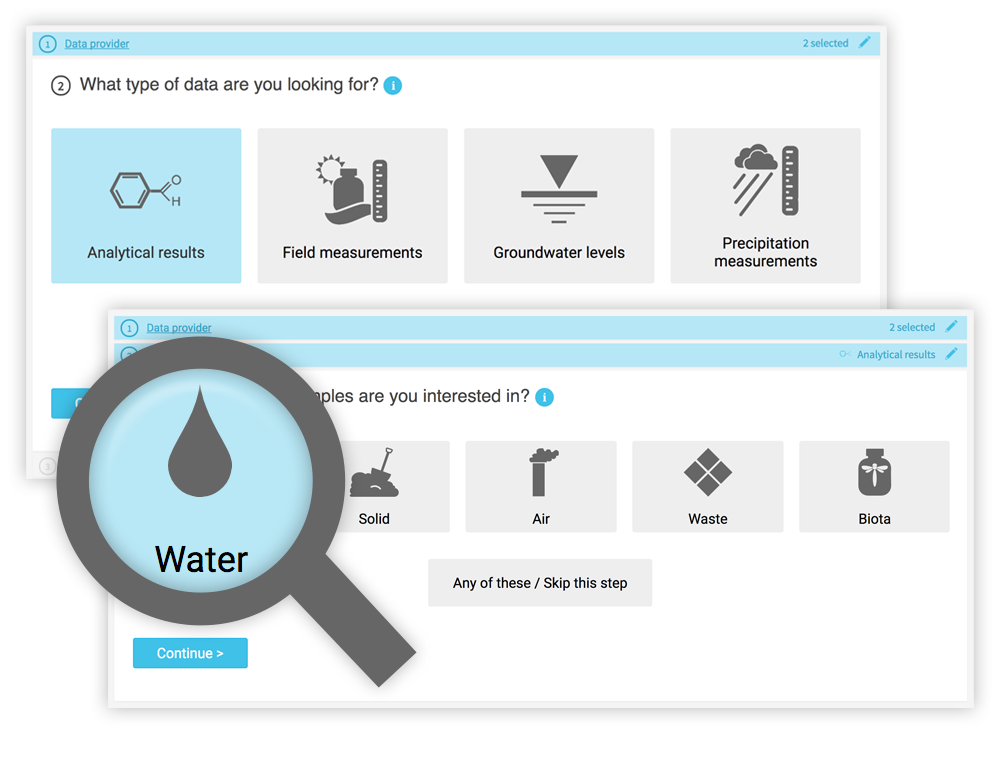

While a knowledgeable environmental scientist may be able to easily navigate a highly technical system, that same operation is bound to be far more difficult for a layperson interested in what chemicals are in their water. Constructing the right query is not as simple as looking for a chemical in water—it really matters what type of water you want to look within. On the Intellus website (showing the environmental data from the LANL site), there are 16 different types of water (not including “water levels”). Using the latest web technologies and our domain expertise, Locus created a much easier way to get to the data of interest.

While a knowledgeable environmental scientist may be able to easily navigate a highly technical system, that same operation is bound to be far more difficult for a layperson interested in what chemicals are in their water. Constructing the right query is not as simple as looking for a chemical in water—it really matters what type of water you want to look within. On the Intellus website (showing the environmental data from the LANL site), there are 16 different types of water (not including “water levels”). Using the latest web technologies and our domain expertise, Locus created a much easier way to get to the data of interest.