Cut your monitoring costs with EIM sample planning

Sample planning can be a valuable and necessary tool for many in highly regulated fields, including water utilities, where adherence to regulatory defined sampling schedules is essential. Moreover, if you have reviewed the drinking water requirements, you know the regulations require complex and variable schedules ranging from monthly samples at routine locations for a set list of parameters to once every five, seven, or nine years at other locations for a completely different list of parameters. Missing a required sampling event can mean fines and public notice to customers.

Other industries face similar complex sampling needs and the financial and reputational impacts can be hefty for missing required samples. So if you are currently an EIM user, or considering an environmental information management system, don’t forget about sample planning components that will save you time and money.

Here are some benefits of Sample Planning that may make you a believer.

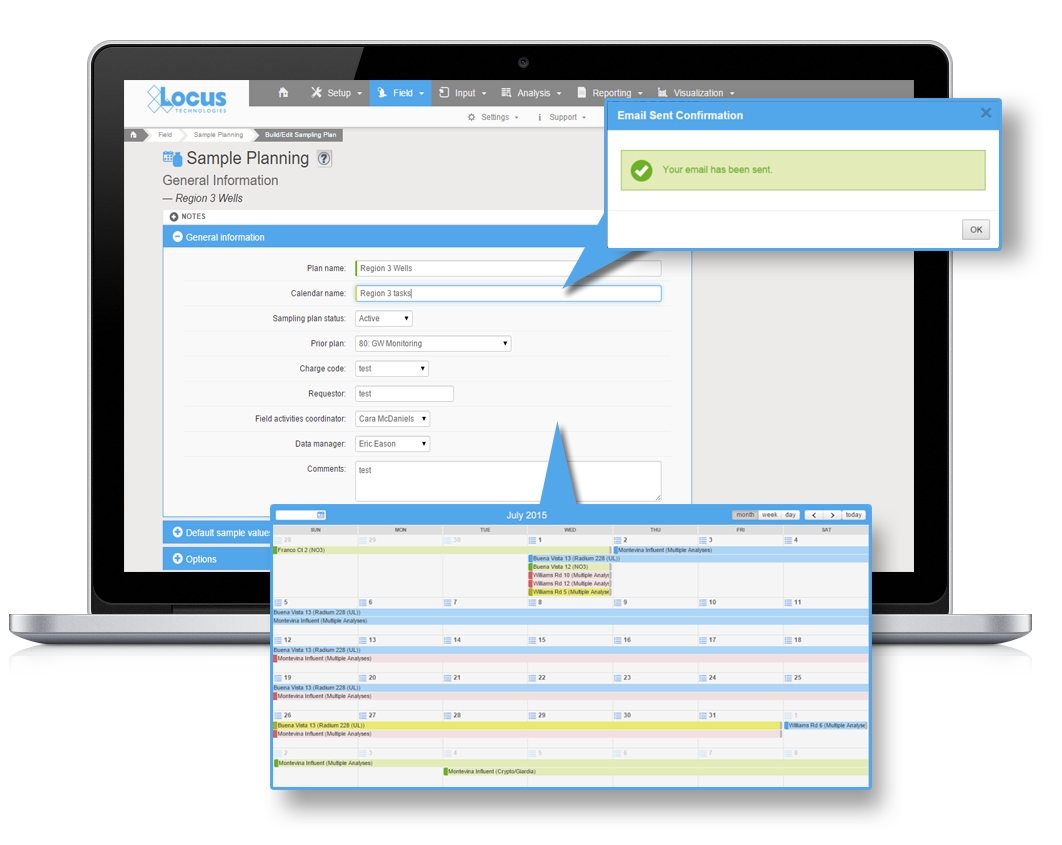

Streamline routine or repetitive sampling – set it up once and reuse or modify as needed

Sample Planning in EIM excels in streamlining repetitive sampling, such as required drinking water samples, or quarterly monitoring well samples. Any sampling events with a schedule from daily to once every 10 years can be planned in EIM’s module and reused again and again, even with tweaks to the schedule for the samples to be collected. Imagine the time savings and the simplicity of having your regulatory requirements all lined out for the year and not have to worry about missing required samples. For water utilities, this is especially valuable given the very strict schedules and the public health implications of missing sampling events.

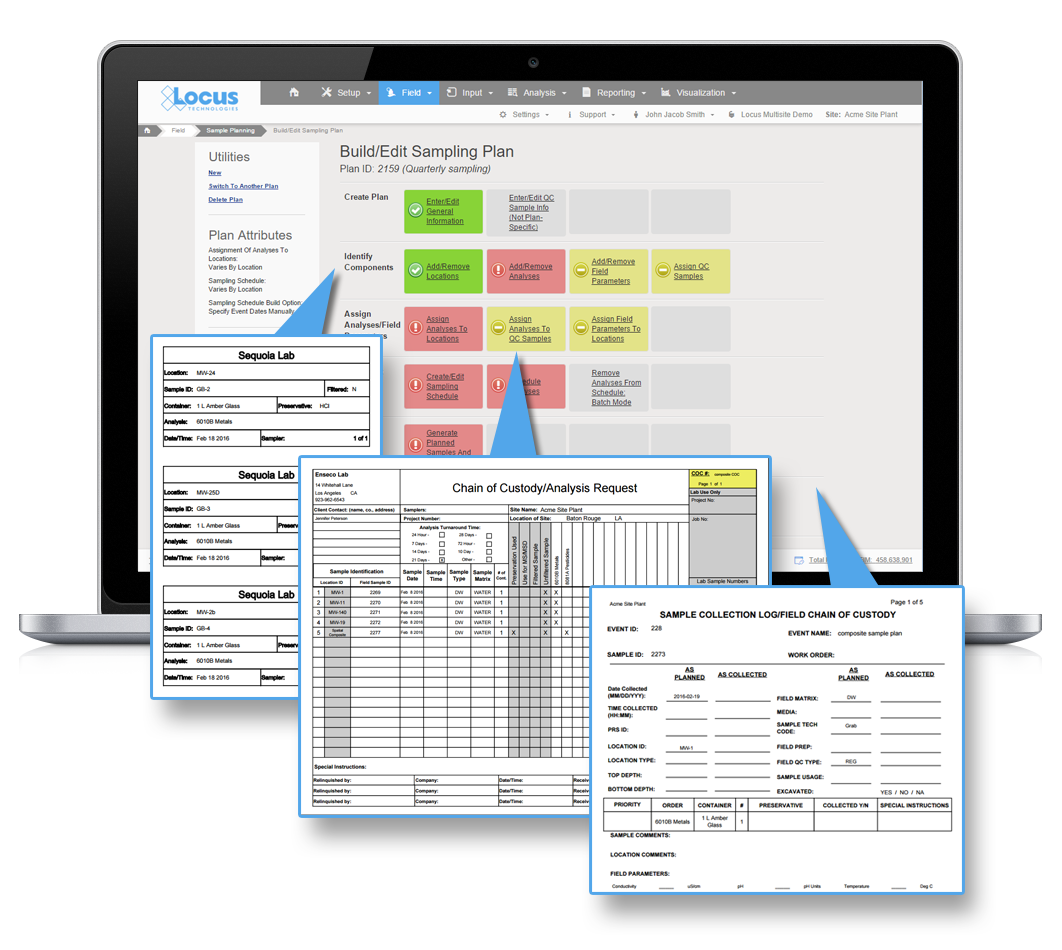

Automatically generate COCs and bottle labels

When samples are planned in EIM, it is a few simple clicks of the mouse to generate COCs, work lists, and bottle labels for the field crew. This saves time for the field and office staff, and helps ensure they collect the needed samples and not miss a collection or a field or laboratory parameter. Moreover, higher levels of accuracy and fewer transcription errors are ensured as sample IDs and requested analyses are printed electronically rather than entered by hand.

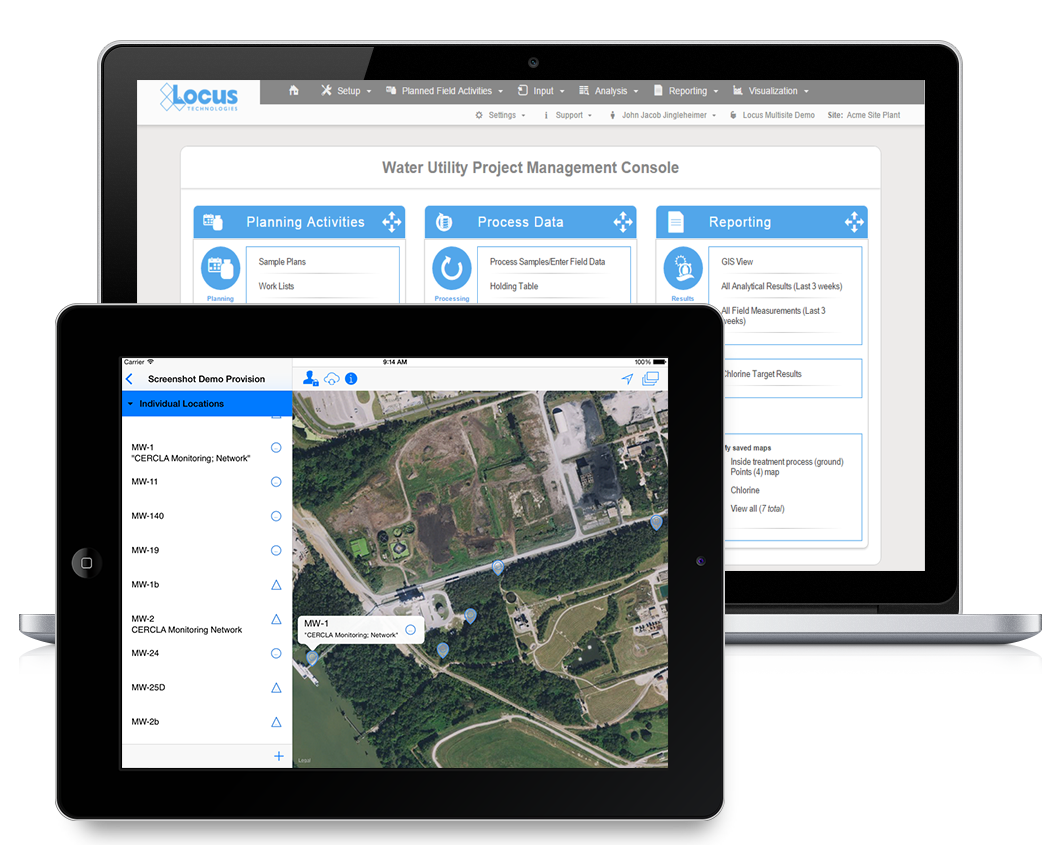

Its fully integrated with Locus Mobile – you can send your Sample Plan to field staff to ensure they collect the samples needed

For customer’s considering using Locus Mobile to streamline their field data collection, Sample Planning is a natural fit. All the samples planned in the Sample Planning module can be delivered directly to Locus Mobile for one or more field staff. You can even have multiple different events sent to the field crew so they can plan ahead in the field. All the collected data is uploaded to EIM in real-time (if service is available) or later (if not) for review and final checks after the field event is concluded. Imagine giving your sampling teams the weekly plan and tracking the progress each day as they sync their data. A handy feature of Locus Mobile, it can remove all the previously collected samples from the plan each day to make your field sampler’s life much simpler.

Larger drinking water utilities will find the integration of Sample Planning and mobile quite appealing, especially with daily sampling by multiple sampling teams and a large number of required routine samples.

All your required field sample information is already in EIM for your sampling event.

All your required field sample information is already in EIM for your sampling event.

When lab data comes back from the lab, you no longer need to enter in the field sample information, it will already be in EIM.

For drinking water utilities, where you may be sampling daily for chlorine at your sample locations, imagine seeing the results across your distribution system instantly, and ability to see it on a map in near real time. Even better, you can share the results with your operations team with a simple dashboard link.

Always know where you stand on your sampling activities

By using Sample Planning, you will know exactly what samples have and have not been collected. You will also know which ones were collected late, and which ones are yet to be collected. This type of information can help ensure you don’t’ miss required samples, and identify schedule impacts when collection is not going according to plan.

When missed samples are identified, its easy to add to the next day’s sampling and send that information to field teams using the integrated mobile app.

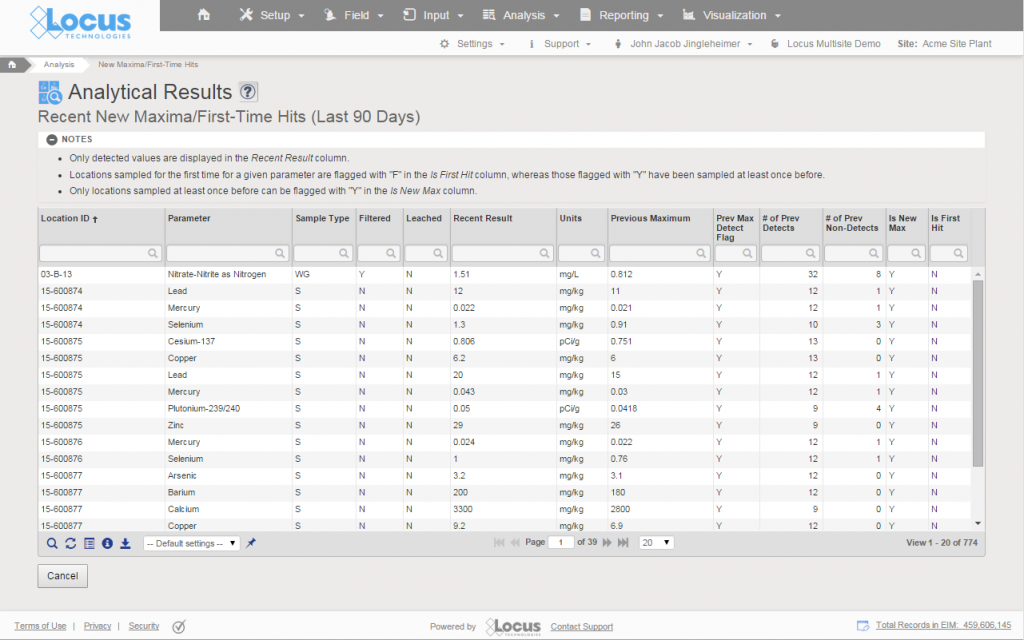

Gain ability to track receipt of laboratory results with fine precision

Gain ability to track receipt of laboratory results with fine precision

For customers that need to track laboratory results down to the method and analyte level, Sample Planning will make that tedious task easy. Therefore, if you ordered an EPA Method 6010C analysis and no result for lead is reported, you will know immediately when the results arrive back from the lab that the deliverable is incomplete. EIM will also tell you when the lab substituted one method for another. You can then decide whether this change is acceptable or not. Because most regulations include a long list of required analytes and acceptable methods, this type of detail is invaluable to help ensure that you remain in compliance.

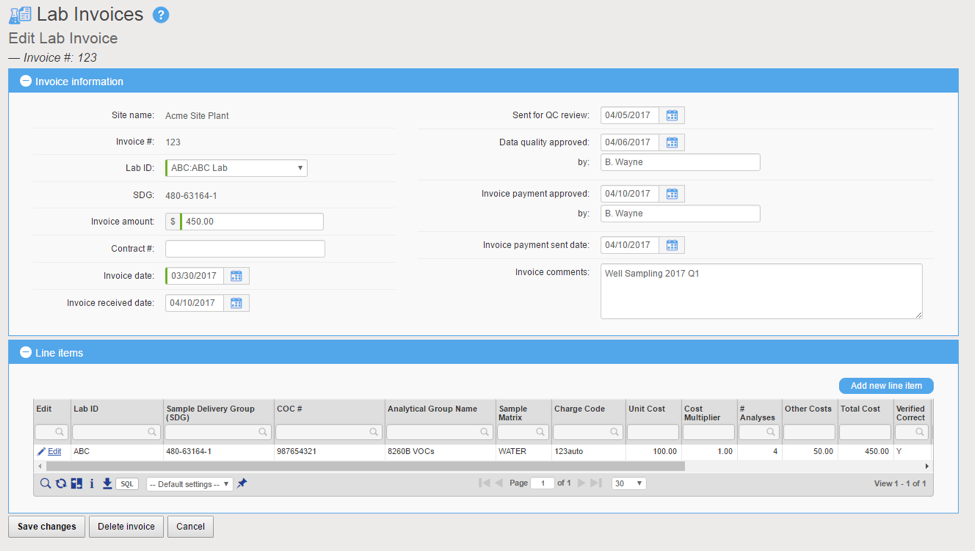

Make review of laboratory invoice easy as pie

Make review of laboratory invoice easy as pie

Trying to review laboratory invoices, especially for large sampling events or complex sampling programs, can be a chore. With EIM’s Sample Planning module, most of the hard work is already done for you. Once you have all your data back, EIM will tell you:

- If the quantity invoiced is more than the order

- If an invoiced line item has been invoiced previously

- If an invoiced line item total cost and/or unit cost is incorrect